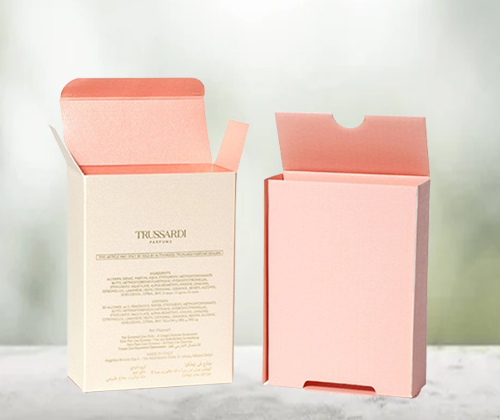

Drawer Perfume Box

Home >> Drawer Perfume Box

Drawer Perfume Box

Custom Drawer Perfume Box

A drawer perfume box is a type of packaging intended exclusively for storing and displaying perfume bottles. It is often made up of a strong cardboard or wooden box with a sliding drawer mechanism that allows quick access to the scents within. The interior of the box typically includes compartments or slots to firmly hold each perfume bottle in place, preventing them from rolling around or becoming damaged during transportation or storage. These boxes are frequently used by perfume makers for gifting or retailing since they provide an elegant and orderly way to display numerous fragrances in a single package.

Service Features

Wholesale | Factory Price

Drawer Perfume Box Designing

The first stage is to design the box, taking into account the dimensions of the perfume bottles, the intended style, and any branding or labeling requirements. Designing a perfume box requires several essential considerations to guarantee that the product is successfully showcased while also being consistent with the brand’s image and target audience. Our skilled designer will help you create a complete design.

- Cardboard or Paperboard: Cardboard or paperboard is a popular choice due to its affordability, versatility, and ease of customization. It can be coated, embossed, or printed with various finishes to achieve different textures and effects. Additionally, cardboard is lightweight, making it suitable for shipping and handling.

- Fabric or Leather: Fabric or leather-wrapped perfume boxes add a touch of elegance and tactile appeal. They are often used for limited edition or gift sets to create a premium unboxing experience. Fabric options include velvet, satin, silk, or linen, while leather provides a luxurious and durable finish.

- Metal: Metal perfume boxes exude sophistication and durability, making them suitable for high-end luxury brands. Common metals used include aluminum, stainless steel, and tinplate. Metal boxes can be embossed, engraved, or coated with finishes like chrome or gold plating for added visual impact.

- Composite Materials: Some perfume boxes may combine multiple materials to achieve a unique look or functional features. For example, a cardboard box with a metal or plastic drawer insert offers the benefits of both materials, combining affordability with durability and aesthetics.

Drawer Perfume Box Cutting and Shaping

The cutting and shaping procedure for a drawer perfume box consists of various phases that transform raw materials into the desired box shape. Luxury boxes manufacturers can easily cut and shape the materials required to assemble drawer perfume boxes. Advanced technologies like as laser cutting and die-cutting serve to assure precision and consistency, while manual methods may be used for smaller-scale or bespoke production.

- Offset Printing: Offset printing is a common method for high-quality, large-volume printing. It involves transferring ink from a printing plate to a rubber blanket, then onto the surface of the box material. Offset printing offers precise color reproduction and can accommodate a wide range of colors and finishes.

- Digital Printing: Digital printing is suitable for short to medium print runs and offers quick turnaround times. It utilizes digital files to directly transfer the design onto the box material, making it ideal for custom or on-demand printing.

- Screen Printing: Screen printing involves pushing ink through a mesh stencil onto the box material. It is suitable for printing bold, vibrant designs on various substrates, including cardboard, paperboard, and plastics. Screen printing involves pushing ink through a mesh stencil onto the box material. It is suitable for printing bold, vibrant designs on various substrates, including cardboard, paperboard, and plastics.

- Specialty Printing: Specialty printing techniques such as foil stamping, embossing, debossing, and spot UV coating can be used to add visual and tactile enhancements to the printed design, creating a luxurious and premium look.

- Structural Design: Determine the size and form of the box depending on the perfume bottle dimensions and any additional products that will be included.

- Graphic Design: Choose a color palette, font, and pictures that convey the desired feelings and perceptions. Incorporate branding components such as logos, slogans, and brand symbols in a consistent and visually appealing manner.

- Print Production: Preparing the design files according to the printer's specifications, including bleed, trim, and color mode (CMYK for print). Printing techniques and finishes that enhance the design, such as embossing, foiling, spot varnish, or textured coatings.

- Artwork and Layout: We will create artwork for the box's design, including the front, back, sides, top, and bottom. Ensure that the layout is balanced and visually appealing, paying special attention to spacing, alignment, and data hierarchy. We will describe in detail how the design will wrap around the box, taking into account any folds or seams.

Work closely with the our designer, you can create a well-designed perfume box that effectively showcases the product, engages consumers, and reinforces the brand’s identity.

Drawer Perfume Box Material

The material used for a drawer perfume box is determined by a variety of considerations, including budget, branding, sustainability aims, and aesthetic appeal. When choosing a material for a drawer perfume box, consider branding consistency, product protection, environmental impact, and cost-effectiveness. Furthermore, obtaining materials from sustainable and eco-friendly sources is consistent with the growing demand for environmentally sensitive packaging solutions.

- Preparation of Materials: Ensure that the chosen material, whether it's cardboard, paperboard, leather, or another material, is properly prepared for cutting. This may involve unrolling large sheets, stacking layers of material, or preparing wooden panels.

- Manual Cutting: For simple shapes and small-scale production, handheld cutting tools such as knives, scissors, or shears may be used.

- Die-Cutting: For precise and efficient cutting of large quantities, a die-cutting machine with custom-made cutting dies is employed. The dies are shaped according to the design and used to stamp out the desired shapes from the material.

- Laser Cutting: Laser cutting machines are used for intricate designs and precise cuts on materials like cardboard, wood, acrylic, and plastic. A computer-controlled laser beam cuts through the material based on the digital design file.

- Shaping and Forming: Once the pieces are cut, they may need to be shaped or formed to achieve the desired box structure. This may involve techniques such as bending, folding, or molding the material into specific shapes using machinery.

Drawer Perfume Box Printing:

Printing is an important factor in improving the visual appeal and brand identification of drawer perfume boxes. Pre-press preparation is the process of preparing artwork files for production prior to printing. This includes ensuring that the design conforms to printing criteria such as color mode (CMYK for full-color printing), resolution, bleed, and trim marks. Various printing processes can be employed to apply graphics to drawer perfume boxes, depending on criteria like as budget, intended effect, and material.

For more detail contact our expert through mail at

print@qasaralmurjan.ae

or

give us call at +971 50 703 3837